Since 2004, Dekuma has been dedicated to developing advanced rubber injection molding equipment tailored for industries such as automotive, electrical power, and engineering vehicles. With years of accumulated expertise, they have built a reputation for delivering reliable machines that serve niche applications like insulator production and rubber track manufacturing. By focusing on technology, materials, and process stability, they provide clients with effective solutions that support consistent output and product quality.

Precision Through Custom Mold Machining

One of the strengths of Dekuma lies in their commitment to custom mold machining. Every core component is designed by their technical team and manufactured under strict standards, ensuring long-term reliability. For applications such as power insulators, where dimensional accuracy is critical, this machining capability allows manufacturers to achieve consistency while reducing the risk of defects. By integrating tailored solutions, Dekuma supports customers in optimizing productivity across specialized product lines.

Advanced Custom Molding Machines for Industry Needs

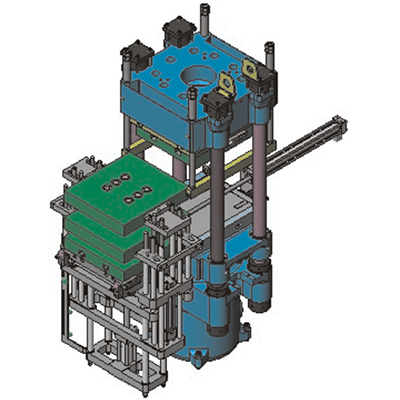

Dekuma also offers custom molding machines that address the requirements of different sectors. In the case of rubber tracks used for agricultural and construction machinery, their equipment is capable of handling demanding materials while maintaining stable performance. These customized machines help businesses meet unique production challenges without sacrificing efficiency. With flexibility in design and operation, Dekuma’s solutions have become a valuable option for companies seeking reliability and adaptability in their manufacturing processes.

Conclusion

By combining expertise in custom mold machining with the versatility of custom molding machines, Dekuma continues to deliver added value for industries that rely on specialized rubber products. Their focus on quality, service, and technological development positions them as a trusted partner for manufacturers seeking long-term, practical solutions in insulator and rubber track production. With a clear mission to innovate and support industrial growth, they remain committed to providing equipment that helps customers achieve both efficiency and durability in their operations.