In the world of woodworking, businesses constantly seek machinery that can streamline their operations. One question that arises frequently is whether a CNC drilling machine can be used as a wood cutter. This query reflects the increasing need for multifunctional equipment that can perform a variety of tasks with ease. HUAHUA CNC has developed machines designed to meet these needs, offering versatile solutions for businesses in the woodworking industry.

The Dual Purpose of CNC Machines: Drilling and Cutting

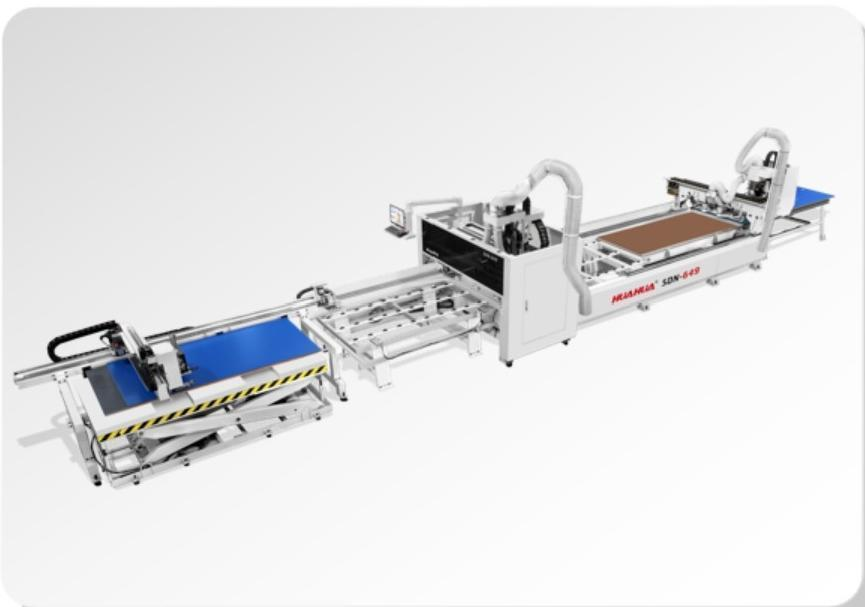

Modern CNC wood drilling machines are designed to be multifunctional. They can perform both drilling and cutting tasks, which significantly reduces the need for multiple machines in a workshop. HUAHUA CNC has engineered machines that combine these two processes into one seamless operation. The machine’s ability to process various panel sizes like 4×8 feet and 4×9 feet allows for efficient handling of materials for both drilling and cutting. This versatility makes it ideal for a range of applications, from furniture customization to large-scale production.

How CNC Drilling Machines Enhance Wood Cutting Precision

Precision is a vital factor in any woodworking process. When using a CNC drilling machine for wood cutting, it’s crucial to maintain high accuracy, especially when dealing with irregular shapes or specific panel dimensions. HUAHUA CNC machines ensure that both drilling and cutting are integrated seamlessly. This integration reduces the chances of errors caused by shifting materials during cutting, a common issue with traditional methods. By keeping everything on the same track and ensuring consistency in measurements, HUAHUA CNC ensures precise and accurate cutting, whether it’s for custom furniture pieces or larger wood components.

Practical Applications for Woodworking with CNC Drilling Machines

Businesses in the woodworking industry are increasingly turning to HUAHUA CNC machines for their dual-function capabilities. These machines are ideal for companies that specialize in custom furniture design or those involved in large-scale manufacturing. By using a CNC drilling machine to both drill and cut, businesses can significantly improve their workflow and reduce the time spent on production. Whether it’s processing panels of different sizes or cutting intricate shapes, the machine’s ability to work simultaneously across multiple stations adds to its efficiency.

Conclusion

While wood drilling machines and wood cutters were once considered separate pieces of equipment, modern CNC drilling machines have evolved to meet both needs. With HUAHUA CNC’s technology, businesses can now use a single machine to perform both drilling and cutting tasks, resulting in better efficiency, precision, and cost-effectiveness. The versatility of CNC drilling machines enables manufacturers to optimize their processes, making it clear that these machines are well-suited for tasks traditionally handled by separate machines.